Links:

- Handle with Care Lastly, aluminium is a sustainable material. It can be recycled indefinitely without losing its quality, making it an environmentally friendly option. As green architecture gains prominence, the use of aluminium window profiles aligns perfectly with the principles of sustainability and responsible construction.

- Slatwall Sliding screen roller replacement is a manageable DIY task that can save you money and enhance your door's functionality. With a little patience and the right tools, you'll have your sliding screen door gliding effortlessly in no time. Regular maintenance and timely replacements can significantly prolong your screen door's lifespan, ensuring years of hassle-free use.

One of the most significant advantages of aluminum window frame extrusions is their exceptional durability. Aluminum is inherently resistant to rust, corrosion, and various weather conditions, making it an ideal material for windows that must withstand the elements. Unlike wood, which can warp, rot, or be affected by termites, aluminum maintains its integrity over time. This strength ensures that the window frames will operate smoothly and remain visually appealing for years, reducing the need for frequent maintenance or replacement.

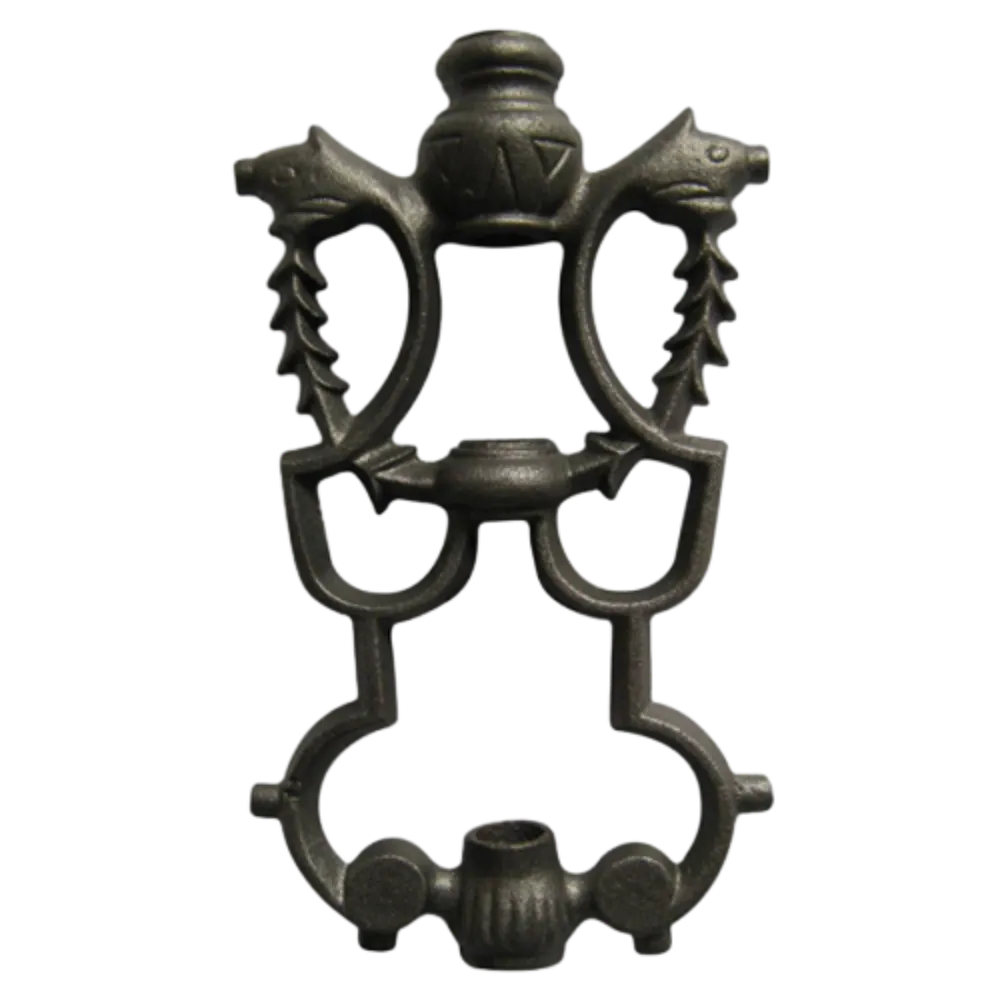

The term wrought iron refers to the process of shaping iron by hand through hammering or bending. This method has been used for centuries to create beautiful and durable structures, including fences. Wrought iron fence spears are known for their ornate details and unique shapes, making them stand out from traditional fencing options. The first step is to remove the door from its track. Start by lifting the door slightly to disengage the bottom wheels from the track. Then, using your screwdriver, remove the screws or pins that hold the top roller assembly in place. Carefully slide the door out of the track, ensuring not to damage the frame or the door itself. In an era where technology has transformed our homes into smart spaces, the importance of securing essential devices such as thermostats cannot be overstated. Enter the steel thermostat lock box - a simple yet effective solution to protect your home's temperature control system from unintended adjustments or misuse. Another aspect of variation in knitting is the exploration of shaping techniques

Cons

Another advantage of aluminium sliding wheels is their lightweight nature. Aluminium is a lightweight material, making it easy to handle and install. This makes aluminium sliding wheels a convenient option for DIY enthusiasts or professional installers alike. Despite their lightweight construction, aluminium sliding wheels are still strong enough to support heavy doors or windows without warping or bending. However, the true value of a cast basket lies beyond its functional aspects. It embodies the philosophy of catch and release, promoting sustainable fishing practices. By providing a safe haven for the fish until it can be unhooked and returned to the water, the basket ensures minimal harm to the aquatic life.Material

In terms of aesthetics, heavy duty sliding door wheels come in various styles and finishes to complement different architectural designs. From minimalist and sleek to more traditional and ornate, there's a wheel design to suit every taste and setting. Furthermore, aluminum is a recyclable material, which aligns with the growing global trend towards sustainable and green construction. End-of-life aluminum products can be recycled without losing quality, contributing positively to the circular economy. Now, measure the old roller to ensure the new one matches in size sliding screen roller replacement. If not, adjust your purchase accordingly. Insert the new roller into the assembly slot, ensuring it fits snugly. Replace any worn-out tracks or brackets as needed. Then, reattach the roller assembly to the door with the screws, tightening them securely but not overly tight to avoid damaging the material.

sliding screen roller replacement. If not, adjust your purchase accordingly. Insert the new roller into the assembly slot, ensuring it fits snugly. Replace any worn-out tracks or brackets as needed. Then, reattach the roller assembly to the door with the screws, tightening them securely but not overly tight to avoid damaging the material. Anodizing

Anodizing cannot peel off. The coating is part of the metal. Anodizing gives aluminum a deeper, richer metallic appearance than is possible with organic coatings. This is because an anodized coating is translucent, and one can see the base metal underneath the coating. Anodizing provides a thin aluminum oxide layer, which will deteriorate over time. Depending on the thickness and quality of the anodization, the surface should last 10-20 years.

This insulating layer can take several forms, e.g. ABS, Noryl or PVC. A fourth possibility is polyamide (also known as PA). This is a high quality plastic that is manufactured from benzene in specialised factories. Polyamide shares a number of advantages with aluminium (wear resistance, 100% recyclable, etc.) but also adds some more.

Here are the steps to follow

Here are the steps to follow  It conjures images of bygone eras when trunks and chests were used to store treasures and memories It conjures images of bygone eras when trunks and chests were used to store treasures and memories

It conjures images of bygone eras when trunks and chests were used to store treasures and memories It conjures images of bygone eras when trunks and chests were used to store treasures and memories